June 2014

38

M

OTOR

C

ONTROL

critical to E: Non Flight critical. DO178B sets

development and compliance standards for

software used in avionic applications.

Analog controllers are also commonly used in

space applications to minimize the cost of ra-

diation-proof components such as processors,

ASICs or FPGAs. Radiation test and character-

ization is still required. Total Dose Testing pre-

dicts the life of the electronics and Single

Event Testing predicts reaction of events such

as solar flares. Manufacturers of these devices

such as Data Device Corporation (DDC) design

to meet common radiation requirements and

perform testing to verify radiation tolerance

performance. Additionally, hybrid microcir-

cuits save space and weight.

Digital motor controllers offer several per-

formance and efficiency advantages that make

them the controller selection of choice for

many applications. The versatility of digital

controllers has advanced as the evolution of

DSP (digital signal processing) and ASIC (ap-

plication-specific integrated circuit) based

processors now enable designers to create flex-

ible products and improve time to market.

The most versatile of these designs are based

on DSP architectures which allow integration

from simpler sensorless systems to complex

multi-axis position control systems. The pro-

cessing power of the DSP, along with associated

graphical user interfaces (GUI), takes the com-

plicated math out of the user design, requiring

only basic knowledge and support to meet the

expected motor system performance goals.

The torque, speed and position loops are often

calculated for the designer based upon motor

and system parameter entry. Many controllers

offer multiple control options.

The embedded control and control logic in the

DSP can contain complex mathematical calcu-

lations and algorithms that are required to

gain the efficiencies of the field-oriented (FOC)

sinusoidal motor commutation technique. This

technique delivers power to the motor by

means of a sinusoidal (sine) waveform. The si-

nusoidal

signal

provides

maximum

voltage/speed in relation to the DC bus voltage

and reduces noise by over 30% relative to a

trapezoidal (trap) drive. The trap drive com-

mutates the motor with a trapezoidal AC signal.

The system losses in a sine drive are in the

motor, while the trapezoidal drive losses are in

the controller. Additionally, a sine wound motor

will improve motor efficiencies as well. The

torque ripple on a sinusoidal motor can be as

low as 1%, while the ripple for a trapezoidal

motor is over 13-14%. The sinusoidal system

also reduces noise, which is essential to meeting

EMI requirements. The trap drive system EMI

signature and current ripple are higher due to

the sharp edges and flatness of a trapezoidal

signal. These signals are modulated by the

PWM frequency in the motor controller.

The processing power of DSPs also enables

flexible motor control that can be utilized in a

wide range of applications, from a sensorless

motor system, such as a fan or pump, to a

complex multi-axis design, such as those that

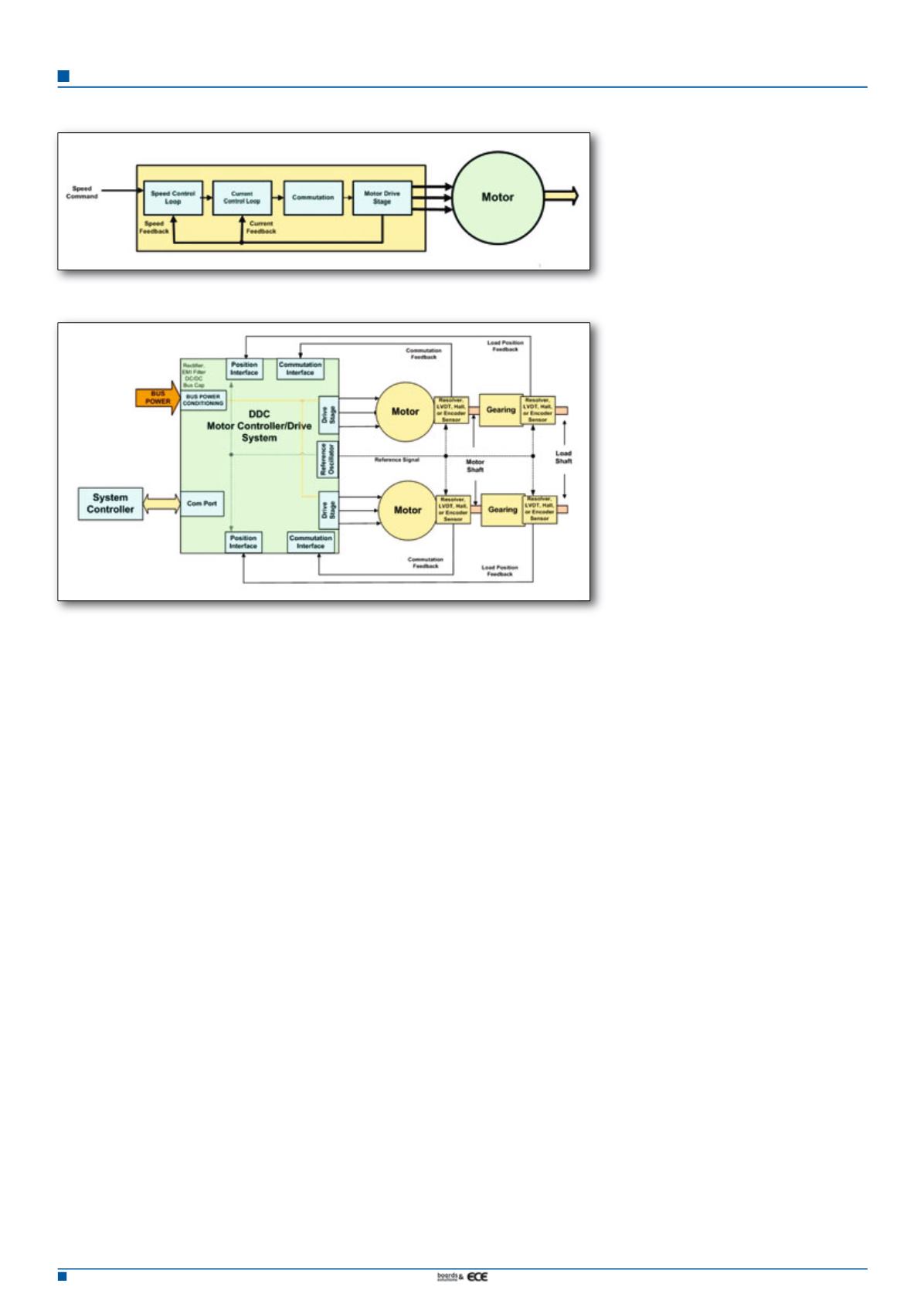

are used in turrets and robotics. The speed

controller uses internal sensing and algorithms

that are required for speed regulation and also

sets the control loop parameters for torque.

Torque is proportional to current and speed is

proportional to voltage. The bandwidth for

the current/torque loop is generally greater

than that of the speed loop.

Torque controllers are used in applications

that require holding torque and changes in di-

rection, since these controllers maintain smooth

transitions in torque through zero speed. This

is known as a four quadrant controller. Con-

trolling current/ torque to the motor will allow

for precision speed control. Torque controllers

utilize a position sensor on the motor to deter-

mine the position of the shaft, in order to en-

ergize the appropriate winding for precision

control. This is most commonly a Hall Effect

device, but can alternatively be resolvers, en-

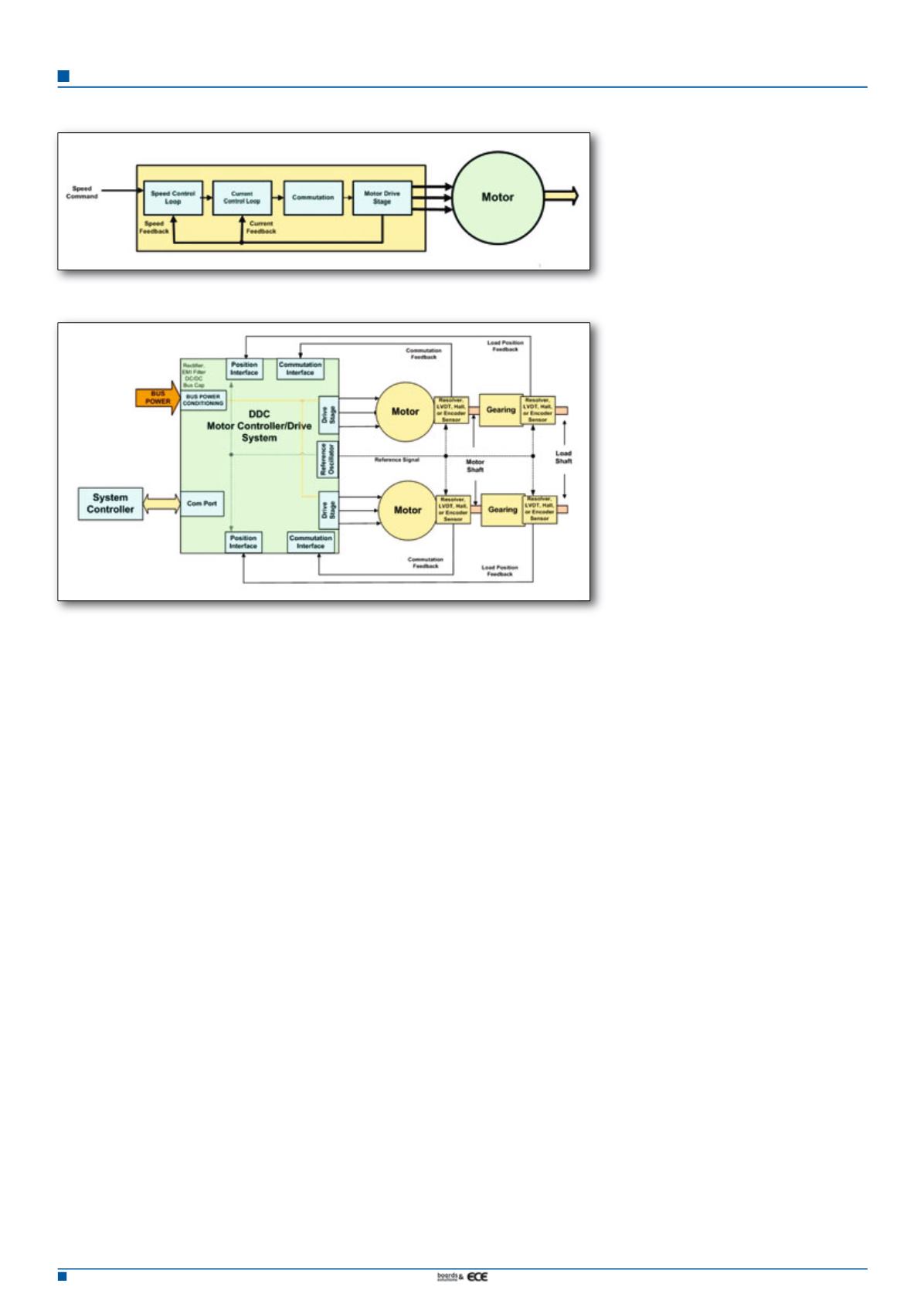

coders etc. A position controller utilizes an in-

terface with position sensors on the motor

and at the load. The position loop is the outer

control loop in this system. The speed and

torque loops must be tuned as well. All three

control loops must be tuned based on the

motor and system parameters.

Programmable motor control devices include

a GUI that will aid and perform these calcula-

tions based upon the motor used and system

requirements. As a system is implemented in

the lab or fielded, system parameters often

change and may require tuning to attain the

desired performance. The GUI is the perfect

tool to minimize the time impact of additional

tuning. Another benefit of tunable controllers

is that a motor can be swapped out and its re-

placement made operational with the simple

change of parameters in a short time. Multiple

motors can be used with the same controller.

This will reduce the cost of ownership which is

a key consideration for motor control systems.

DSP-based solutions also allow for interfacing

with host processor controlled systems that

communicate on serial networks such as CAN,

RS-485, RS-422 etc. Alternatively, speed and/or

torque can be set by means of an analog

voltage input when advanced features are not

required. Also, on-board or system processors

can coordinate 2-axis movement as required

in satellite base stations, radars, turrets or ro-

botic systems. Motor control suppliers such as

Data Device Corporation offer products that

incorporate all control algorithms and sensor

interfaces, as well as provide advanced protec-

tion, such as overtemperature, overcurrent,

Sensorless motor control system

Dual-axis motor control