When failure can result in damage to the en-

vironment, significant property destruction

or even loss of life, the application requires an

embedded safety-critical system. In railway

applications, no margin of error is tolerable;

there is no opportunity to “tweak” improve-

ments on the fly or to allow for unanticipated

problems. The three major contributors to

unacceptably dangerous outcomes in railway

embedded control systems include: component

failure; system imbalances; and human error.

Fortunately, designers have an arsenal of es-

tablished standards and guidelines they can

use to greatly reduce the odds of a system

failure that can result in catastrophic damages.

By employing a methodical, verified and doc-

umented series of processes that span the full

scope of product development and implemen-

tation, the chances of having a reliable system

with functional safety are much greater.

The railway market is an important area for

these types of systems. The world market in

the transportation industry is estimated at

$200 billion, with an annual growth rate of

2% to 3%. A global initiative driving new op-

portunities within the rail industry is auto-

mated train control (ATC) and operation on-

train and wayside. In turn, the key driver for

ATC is increased safety for trains and increased

comfort for passengers. More specifically, op-

portunities exist in new technologies for sig-

naling systems and safety-critical sub-segments.

These opportunities are evolving in Europe,

USA, Australia, China and Russia.

An example of ATC in the US is positive train

control (PTC), which is technology that pre-

vents train-to-train collisions. PTC is being

driven by the Rail Safety Improvement Act of

2008 (RSIA). The act has mandated widespread

installation of PTC systems on freight rail by

2015. A comparable scenario is unfolding in

Europe spurred by the European Rail Traffic

Management System (ERTMS). The European

Union aims to enhance cross-border interop-

erability and signaling procurement by creating

a single European standard for train control

and command systems. Transportation safety

in other areas of the world is developing as

well. China has an initiative similar to that of

the US and Europe – the Chinese Train Control

System (CTCS). With over 90,000 km of rail

in China, this is a huge growth opportunity

for suppliers of safety- and mission-critical

systems. The infrastructure that needs to be

built out for each of these initiatives is immense,

and communications cannot be halted, even

for a minute, if passenger safety is to be

ensured. As these rail systems grow in use as

well as in speed, each systems will need to

know exactly where each train is, how each is

operating, and what state it is in.

A general standard, IEC 61508 by the Interna-

tional Electrotechnical Commission, covers func-

tional safety in electronic systems. It defines the

Safety Integrity Levels SIL 1 up to SIL 4. Manu-

facturers are obliged to find out the necessary

SIL for safety-relevant systems or functions by

carrying out a hazard and risk analysis. It gives

the measure for the effectiveness of a safety

function and is expressed by the probability of

failure of this function. Different scenarios

match a defined scale of numerical values.

Several bodies have added specific standards

for the varying industries and applications.

For railways, the European Committee for

Triple redundant single-board computer

based on three PowerPC 750 CPUs

B

OARDS

& M

ODULES

By Susanne Bornschlegl,

MEN

This article introduces triple

redundant single-board

computers based on three

PowerPC 750 CPUs operating

in lockstep architecture.

Compared to solutions using

three individual CPU boards,

the one-card approach

is much more compact

and reduces both software

overhead and power

consumption.

June 2014

16

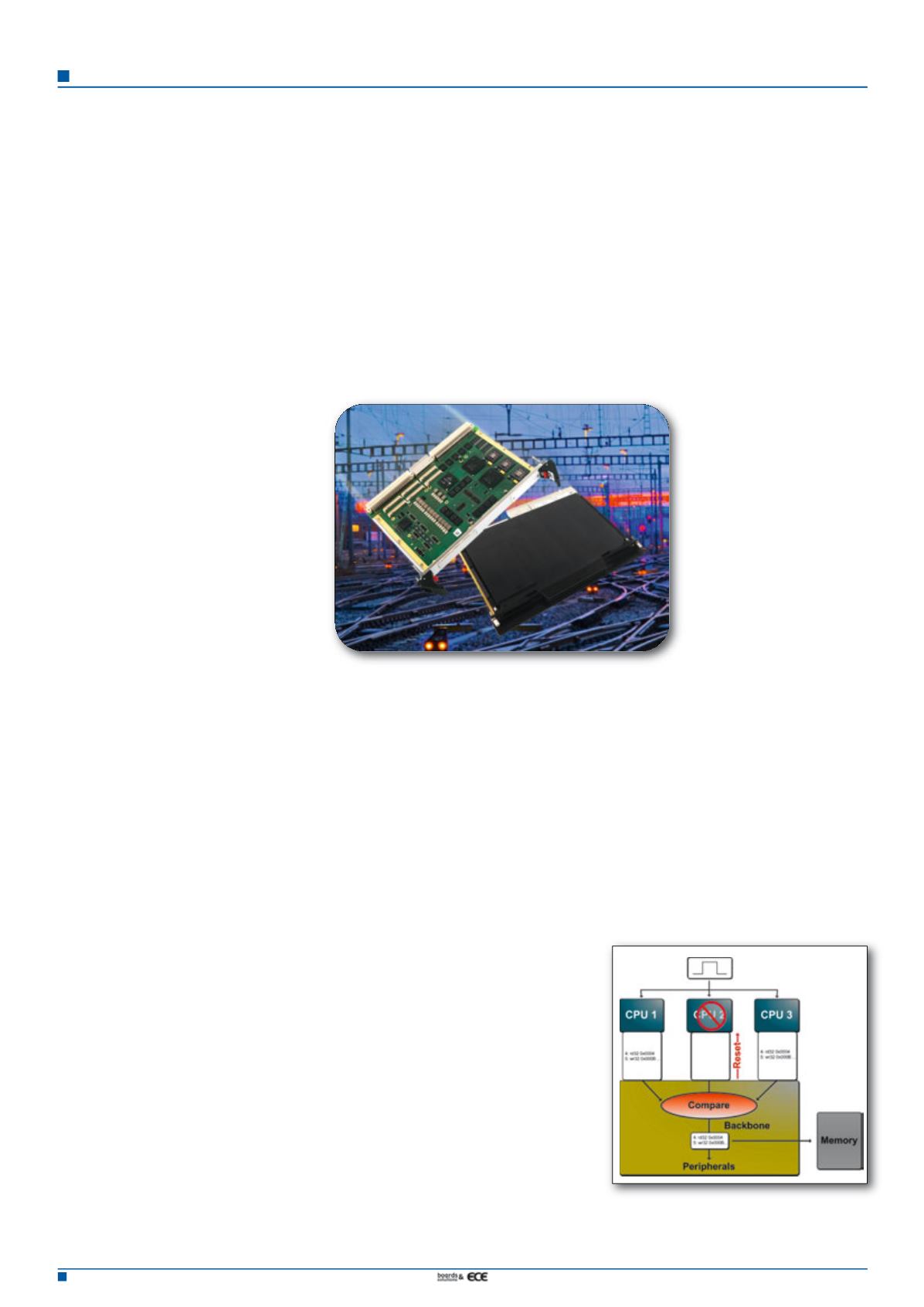

Figure 1. Triple-redundant system: two out of

three subsystems must operate correctly.