October 17

8

C

oVEr

s

torY

hardware. Traditionally, leading machine

and robot manufacturers used to develop

their own controller boards. However, with

new generations of CPUs being launched at

accelerated speeds and machine equipment

needing to incorporate the latest functions to

meet Industry 4.0 demands, manufacturers

are forced to change their controller board

designs more frequently. This requires time

and leads to delays in passing certifications so

ultimately results in increased time-to-market.

To circumvent these problems, manufacturers

need to start to evaluate the use of embedded

Computer-on-Modules (COMs) for custom-

izing their control boards. With these off-the-

shelf available COMs, machine performance

can be upgraded to the latest CPU with a sim-

ple module replacement. There is no need to

redesign the entire control board, which helps

to significantly accelerate the product devel-

opment cycle.

The COM design model, which combines the

core module and a customized carrier board,

has the advantage of boosting flexibility. Yet

there are further challenges to overcome. First

of all, a COM is not a complete single board

computer; it is the system core and controls

peripheral applications via interfaces and spe-

cialized functionality on the carrier board. In

the case of equipment malfunction, the added

complexity may make it more difficult to

identify whether the source of the problem

lies in the carrier board, COM or peripheral

cards. Therefore, without help from a team of

experts, locating the root cause can be time

consuming. In addition, manufacturers with

ambitions to develop intelligent machine or

robotics solutions tend to engage in projects

that are diverse and often involve complex

requirements such as firmware changes and

BIOS customizations. Support for multiple

operating systems including Windows, Linux,

RTOS and virtualization is also required

so specific development kits are needed to

ensure smooth development of both the car-

rier board and software. However, as many

suppliers are outsourcing a large part of their

development work to third-party vendors and

have no plan to train their own software engi-

neers, they lack the ability to solve problems

independently and to promptly provide the

necessary technical support.

A leading international robotic arm manufac-

turer faced the challenges described during its

transition from internally designed controller

boards to the adoption of the COM concept.

ADLINK Technology comprehensive COM

starter kits – specifically tailored to fulfill

not only individual but all requirements for

industrial automation and robotic applica-

tions, complete with reference designs – were

able to eliminate most of the challenges of the

customer. When the customer encountered

difficulties during development, the techni-

cal team responded quickly and effectively to

assist in addressing system integration issues,

whether or not they were directly related to

the COM. When necessary, highly trained

ADLINK staff visited the customer location

to find the root cause of the problem as it is

the company goal always to provide profes-

sional support to customers during the entire

development process. If module vendors have

their own signal measurement laboratories,

they can help customers also in measuring all

computer input and output signal waveforms

to ensure that COM design and manufactur-

ing comply with all the required standards.

Yet helping customers during the design-in

process of a module is not the only service

COM vendors can offer. They can support

them even more comprehensively by pub-

lishing complete design for manufacturing

(DFM) verification principles for the product

design-in stage. All those efforts aim to guar-

antee highest product compatibility and reli-

ability as well as fastest time-to-market. Close

collaboration with Intel is helping firms such

as ADLINK to launch new COM products the

day new processors for the embedded mar-

kets become available, so that OEM engineers

can instantly upgrade their control systems

with the very latest Intel processor technology,

allowing really fast and also highly reliable

time-to-market strategies.

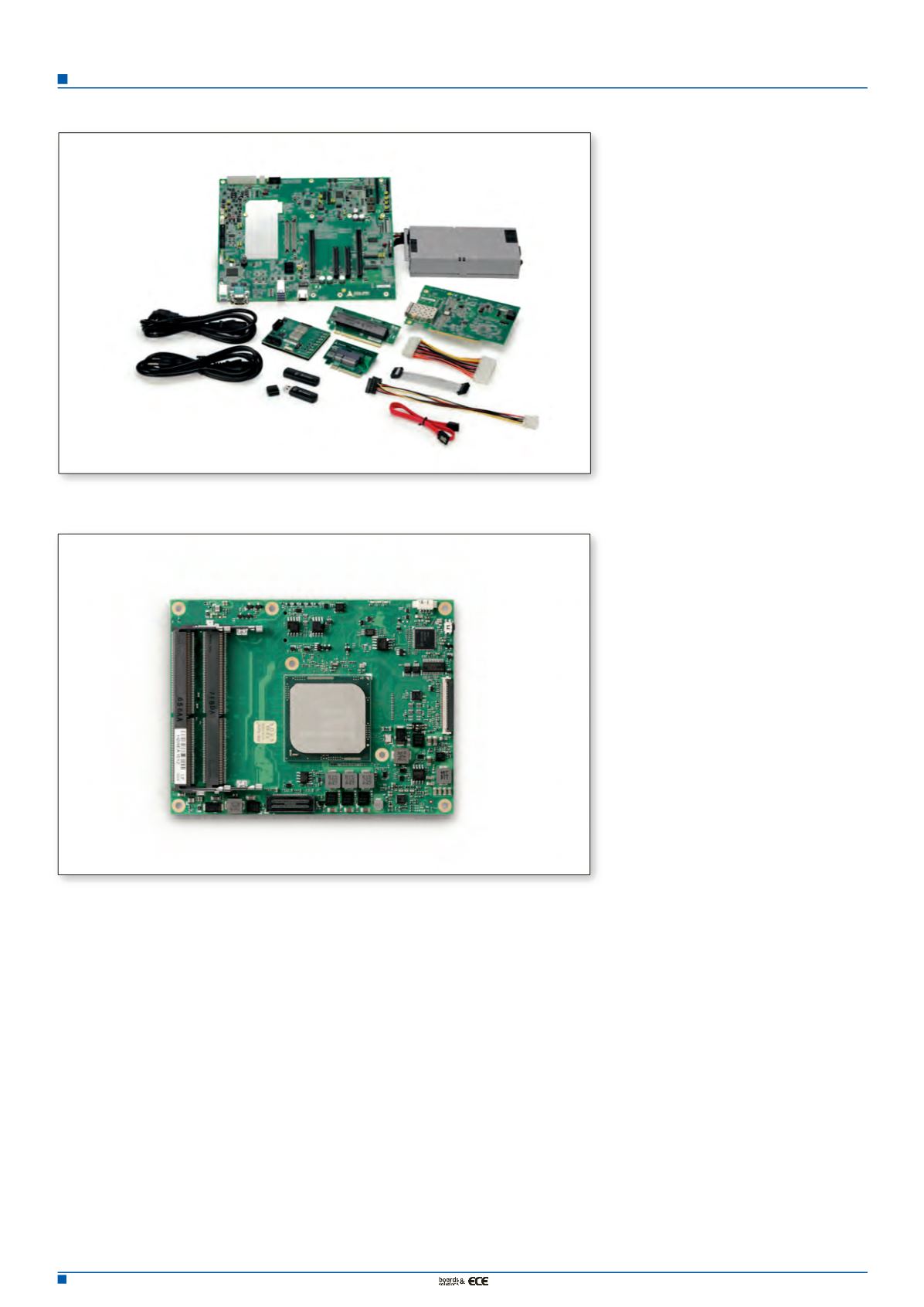

Figure 1. The rugged starter kits are tailored for Industry 4.0 and collaborative robotic

applications and come complete with reference designs for various purposes

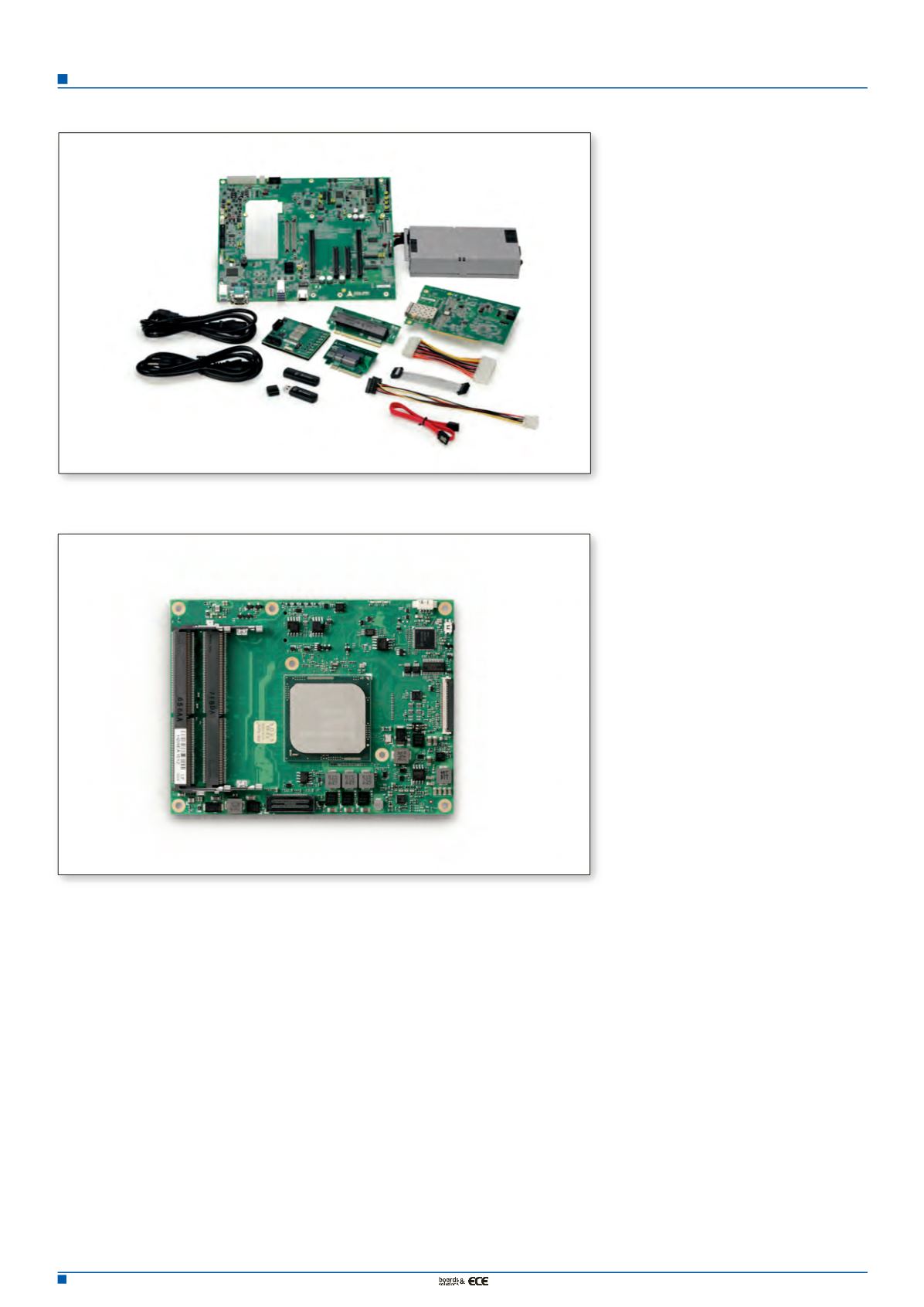

Figure 2. Thanks to their 10 GbE interfaces and massive PCIe support, the brand-new COM Ex-

press Type 7 Computer-on-Modules from ADLINK Technology are tailored for Industry 4.0 server

and collaborative robotic applications